Polystyrene Recycling

Polystyrene is a versatile plastic material widely used in a variety of applications due to its light weight, durability, and ease of molding. It is a polymer made from the monomer styrene, which is a liquid hydrocarbon derived from petroleum.

Types of Polystyrene

There are several forms of polystyrene, each serving different purposes:

-

General-Purpose Polystyrene (GPPS):

-

Characteristics: Transparent, brittle, and rigid.

-

Uses: Used in products like disposable cutlery, CD cases, and laboratory ware.

-

-

High-Impact Polystyrene (HIPS):

-

Characteristics: More impact-resistant due to the addition of rubber, making it tougher.

-

Uses: Commonly used for items like food containers, refrigerator liners, and toys.

-

-

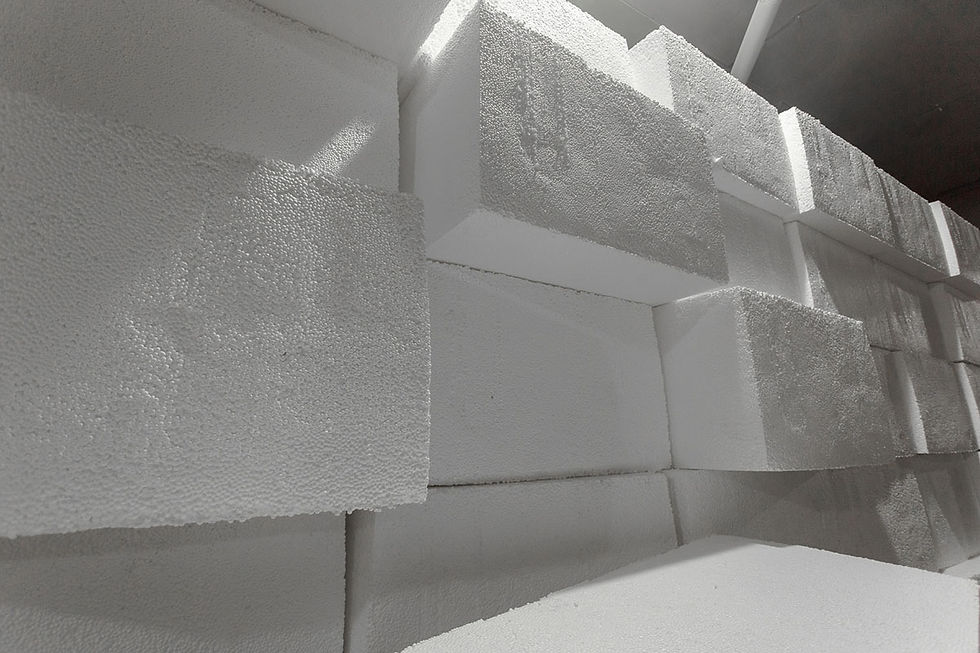

Expanded Polystyrene (EPS):

-

Characteristics: Light, buoyant, and insulating, made by expanding polystyrene beads.

-

Uses: Often used for packaging (e.g., foam peanuts), insulation, and in building materials.

-

-

Extruded Polystyrene (XPS):

-

Characteristics: Similar to EPS but with a denser structure, offering better moisture resistance and thermal insulation.

-

Uses: Used in construction for insulation panels, underlayments, and in model building.

-

PS Recycling Service

What Is Polystyrene?

Petroleum is made into a liquid hydrocarbon called styrene, which is then converted into polystyrene. This is through a chemical process known as suspension polymerization. Due to this type of plastic structure, polystyrene is incredibly difficult to degrade.

Polystyrene is a hydrocarbon that is used for a wide array of applications. Some examples include food packaging material, food trays, and other consumer polystyrene packaging such as polystyrene cups. Extruded polystyrene (XPS) is often used in ceiling insulation. Polystyrene’s toxic nature also makes some products hazardous, meaning they must be disposed of professionally.

You may also have EPS packaging which is formed as a white polystyrene foam produced from solid beads. Recycled EPS waste can be turned into items such as frames and other materials such as insulation.

Expanded polystyrene (EPS) is the most common type of polystyrene found on the modern market. This material is widely used to package food and drink goods, and also in the construction industry. It adds a robust foam barrier to packaging that can keep your goods safe during transport.

%20copy.png)

How Is Polystyrene Recycled?

There are three common methods of recycling, known as granulation, compacting, and densifying. They work as follows:

Granulation: Lighter density forms of polystyrene can go through a machine known as a granulator. This machine separates down to the tiny beads that make it up, which are then are mixed into unused polystyrene granules.

In these cases, there is no reduction to the strength, insulating properties, or other qualities of the material. Recycled EPS has all the same benefits of brand new polystyrene after it has gone through granulation.

Compacting: For denser forms of polystyrene, they have to go into a compactor that presses them together. The resulting material is a very heavy and thick bale of pure polystyrene. These bales go through a machine that then shreds them into new General Purpose Polystyrene Pallets.

Densifying: There are other methods of recycling that are used less frequently, too. For instance, expanded polystyrene can be fed into a machine called a foam densifier.

After it’s shredded, this machine exposes the foam to heat and pressure. Once melted down into a paste, the material that is then cooled into a block of solid polystyrene, extracting all of the air.

The blocks of polystyrene can then be shredded into new general purpose polystyrene pallets.